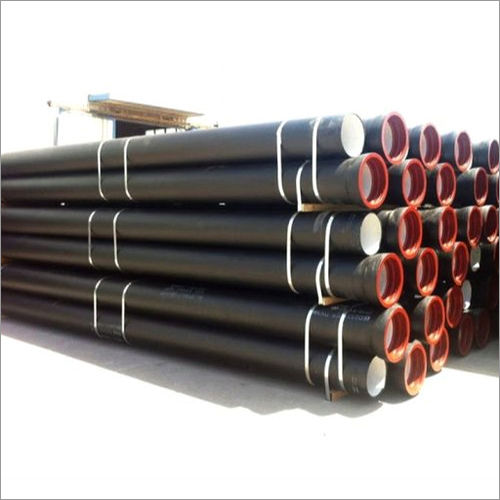

Ductile Iron Flanged Pipes

Product Details:

- Temperature Range -10C to +70C

- Flexibility Rigid

- Yield Strength >= 300 MPa

- Diameter 80 mm to 1200 mm

- Tensile Strength >= 420 MPa

- Sealing Type Gasket (Rubber or EPDM)

- Coating Type Internal cement mortar, External fusion bonded epoxy

- Click to view more

X

Ductile Iron Flanged Pipes Product Specifications

- 5 mm - 20 mm (depending on diameter)

- >= 300 MPa

- Rigid

- -10C to +70C

- Gasket (Rubber or EPDM)

- 80 mm - 1200 mm

- 80 mm to 1200 mm

- >= 420 MPa

- Fusion Bonded Epoxy Coated

- 1% on dimensions

- Ductile Iron Flanged Pipes

- Water transmission, wastewater, fire fighting lines, industrial fluid conveyance

- Flanged Ends

- Cylindrical Pipe

- Up to 6 meter/12 meter

- K7 / K9

- IS 8329 / ISO 2531 / EN 545

- Internal cement mortar, External fusion bonded epoxy

- Round

- Ductile Cast Iron

- Not flexible (Rigid pipe)

- Flanged

- Water Supply, Sewage, Industrial Pipeline, Irrigation

- PN 10, PN 16, PN 25

- Dark Blue, Black

- Flanged joint with bolts and gaskets

- Up to 1.5 times rated pressure

- Internal cement lining and external epoxy/bitumen coating

- Protective temporary end caps

- Standard and batch number printed on pipe

- Varies according to diameter and length (request data sheet for details)

- Loose or bundled as per customer requirements

- Underground and Overground

Product Description

Orbit Tradex Pvt Ltd has an expertise in providing Ductile Iron Flanged Pipes to its customers. These pipes have different pressure ratings, for example PN1.0 and PN 1.6, to specify a few. The flanges are the flat rings around the edges which are tightened or screwed to fit.

Applications:

- Used mostly in over the ground Pipelines, Elevated reservoirs, Exposed installations

- Provisional or temporary installations, where disengagement or dismantling is required.

- Fire Fitting Systems

- Ideal for Hilly areas, slopes

Technical Specifications

| Product Name | Ductile Iron Pipe |

| With Restrained Joints With Flanged Joints | |

| Class of Pipe | C20, C35, C30, C40,C50,C64 and C100 |

| Size Range | DN 80mm to DN 1200mm |

| Standard Length | 5.5m/ 6.0m |

| Internal Linings | Cement* Lining |

| Cement Lining with Bituminous Seal Coat | |

| Cement Lining with Epoxy Seal Coat | |

| Polyurethane | |

| *Cement Type: OPC/Sulphate Resistant Cement/ Blast Furnace Slag Cement/ High Alumina Cement | |

| Outside Coatings | Zinc Coating (130gm/m^2 or 200gm/m^2 or 400gm/m^2) with finishing layer of Bitumen/ Blue Epoxy/ Red Epoxy |

| Alloy of Zinc and Aluminium with or without other metals having a minimum mass of 400gm/m^2 with Finishing Layer of Bitumen/Blue Eposxy/ red Epoxy | |

| Outside Onsite Protection | Polyethylene Sleeving |

| Coating | Bitumen/Eposy/Polyurethane or as per customer requirement. |

| Conforming Specifications | ISO 2531; BSEN 545; BSEN 598; ISO 7186; IS 8329 |

Comprehensive Corrosion Protection

Each ductile iron flanged pipe is internally lined with cement mortar and externally coated with fusion bonded epoxy or bitumen. This dual-layer protection secures the pipes against corrosion, ensuring longevity even in harsh environments. Temporary end caps are fitted to prevent contamination during handling and transportation, which is particularly beneficial for water transmission and industrial pipelines.

Precision Manufacturing Standards

Manufactured to strict tolerances of 1% and marked with standard and batch numbers, every pipe meets the requirements of IS 8329, ISO 2531, and EN 545. Hydrostatic testing at up to 1.5 times rated pressure guarantees performance and safety. Available in thicknesses from 5 mm to 20 mm, these pipes can handle rated pressures of PN 10, PN 16, or PN 25 as specified.

Versatile Application and Easy Installation

Fitted with flanged ends, bolts, and robust gaskets, these pipes can be quickly joined for both underground and overground use. Their rigidity and robust sealing minimize leakage risk, making them ideal for water supply, sewage, irrigation, and fire fighting lines. Packing can be customized as loose or bundled to accommodate specific site requirements.

FAQs of Ductile Iron Flanged Pipes:

Q: How are ductile iron flanged pipes joined and sealed?

A: These pipes feature flanged ends that are connected using bolts and gaskets, typically made of rubber or EPDM. This design creates a secure, leak-proof seal suitable for both underground and overground installations.Q: What kind of corrosion protection is provided for these pipes?

A: To ensure long-term durability, the pipes are coated internally with cement mortar and externally with fusion bonded epoxy or bitumen. This protects against corrosion from water, wastewater, and industrial fluids.Q: When should I choose flanged joint ductile iron pipes over other types?

A: Flanged joint pipes are ideal when you need strong, rigid connections that can be easily assembled or disassembled, particularly in water supply, fire fighting, and industrial pipeline systems where secure sealing and durability are priorities.Q: Where can ductile iron flanged pipes be installed?

A: These pipes are suitable for both underground and overground applications, allowing use in municipal water supply, wastewater networks, etc. Their robust construction supports installation in varied environments.Q: What is the typical process for handling and installing these pipes?

A: The pipes are delivered either loose or bundled, with protective end caps. Installation involves aligning the flanges, fitting gaskets, and bolting the joints securely. Hydrostatic testing should be conducted after assembly to verify sealing integrity.Q: What are the main benefits of using ductile iron flanged pipes?

A: They offer high mechanical strength, reliable sealing, long service life due to advanced corrosion protection, and compliance with international standards. Their versatility supports application in water, sewage, industrial, and firefighting pipelines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email