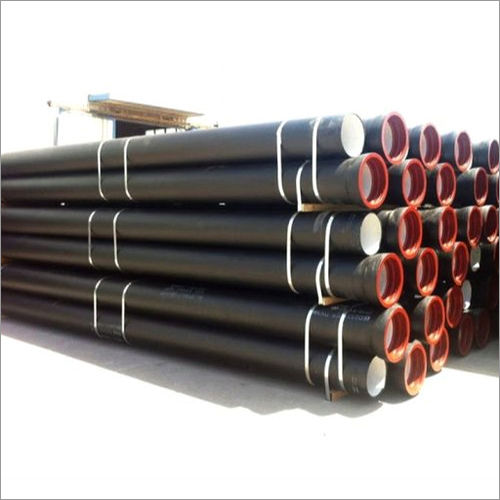

Industrial Ductile Iron Pipes

500 INR/Piece

Product Details:

- Connection Type Push-on, Flanged, Mechanical Joint

- Yield Strength Minimum 300 MPa

- Tolerance 1% or as per standard

- Flexibility High - withstands ground movements

- Diameter 80 mm to 1000 mm

- Tensile Strength Minimum 420 MPa

- Sealing Type Rubber Ring/Gasket

- Click to view more

X

Industrial Ductile Iron Pipes Price And Quantity

- 500 Piece

- 500.00 - 1000.00 INR/Piece

- 500 INR/Piece

- Zinc coating with bituminous overcoat

- Tyton, Flanged, Mechanical joints available

- Excellent (high resistance to mechanical impact)

- Water, Raw water, Wastewater, Slurry

- Up to 50 bar (as per pipe class)

- Over 50 years under standard operating conditions

- Available on request (special thicknesses, coatings, lengths)

- Class K7, K8, K9, K12 as per design

- Cement mortar lined as per ISO 4179

- Loose or bundled for bulk transport

- Enhanced by internal and external coatings

- 5D as per manufacturer recommendation

Industrial Ductile Iron Pipes Product Specifications

- High - withstands ground movements

- 80 mm to 1000 mm

- Black / Blue / Red

- Cylindrical

- 1% or as per standard

- Round

- GJS 500-7 / GGG 50 / GGG 40

- Industrial Ductile Iron Pipes

- External Zinc coating with Bitumen/Epoxy finishing, Internal Cement Mortar lining

- Push-on, Flanged, Mechanical Joint

- Minimum 300 MPa

- Ductile Iron

- DN 80 mm to DN 1000 mm or as per requirement

- Variable, typically allows some deflection at joints

- IS 8329 / ISO 2531 / EN 545 / EN 598

- As per class & standard (generally 6 mm to 15 mm)

- Zinc with Bitumen/Epoxy, Internal Cement Lining

- Socket & Spigot with Rubber Gasket

- -10C to +60C

- Not Applicable (mainly push-on/flanged ends)

- Up to 6 meters (custom lengths available)

- Water Supply, Sewage, Irrigation, Industrial use

- Rubber Ring/Gasket

- PN 10 / PN 16 / PN 25 (as per project requirements)

- Water distribution, Drainage, Fire fighting lines, Industrial pipelines

- Minimum 420 MPa

- Zinc coating with bituminous overcoat

- Tyton, Flanged, Mechanical joints available

- Excellent (high resistance to mechanical impact)

- Water, Raw water, Wastewater, Slurry

- Up to 50 bar (as per pipe class)

- Over 50 years under standard operating conditions

- Available on request (special thicknesses, coatings, lengths)

- Class K7, K8, K9, K12 as per design

- Cement mortar lined as per ISO 4179

- Loose or bundled for bulk transport

- Enhanced by internal and external coatings

- 5D as per manufacturer recommendation

Industrial Ductile Iron Pipes Trade Information

- 1000 Piece Per Day

- 1 Week

Product Description

Order the new release of elite Industrial Ductile Iron Pipes, engineered for exceptional impact resistance and remarkably enhanced corrosion protection. These sought-after pipes feature impeccable internal cement mortar lining as per ISO 4179 and a robust external zinc coating with a bituminous overcoat, ensuring long-term performance. Available in Class K7, K8, K9, and K12, with Tyton, flanged, and mechanical joints, they are ideal for water, wastewater, slurry, and industrial fluids. Impressive flexibility, custom options, and a service life exceeding 50 years make them the prime choice for demanding infrastructure projects. Supplied by leading distributors and manufacturers across India.

Purpose-driven Features and Applications

Industrial Ductile Iron Pipes are widely used for water supply, sewage, irrigation, and industrial pipeline networks. Renowned for their high impact and corrosion resistance, these pipes are indispensable in water distribution, drainage, fire-fighting lines, and slurry management. Used by municipal bodies, infrastructure developers, and industrial facilities, they are favored for dependable joints, customization, and durability. Available in round section shapes, spanning DN 80 mm to DN 1200 mm, their robust construction meets IS 8329, ISO 2531, and EN standards.

Payment Terms, Sample Policy & Delivery Process

Payment terms for Industrial Ductile Iron Pipes are flexible as per client agreement, with samples available upon request. Once an order is confirmed, samples are handed over for customer evaluation, ensuring satisfaction before bulk delivery. Pipes are delivered securely, either loose or bundled, to guarantee impeccable packaging and transit safety. Our streamlined process ensures products reach you in optimal condition, ready for immediate deployment in projects. Contact us for tailored payment structures and sample availability in India.

Purpose-driven Features and Applications

Industrial Ductile Iron Pipes are widely used for water supply, sewage, irrigation, and industrial pipeline networks. Renowned for their high impact and corrosion resistance, these pipes are indispensable in water distribution, drainage, fire-fighting lines, and slurry management. Used by municipal bodies, infrastructure developers, and industrial facilities, they are favored for dependable joints, customization, and durability. Available in round section shapes, spanning DN 80 mm to DN 1200 mm, their robust construction meets IS 8329, ISO 2531, and EN standards.

Payment Terms, Sample Policy & Delivery Process

Payment terms for Industrial Ductile Iron Pipes are flexible as per client agreement, with samples available upon request. Once an order is confirmed, samples are handed over for customer evaluation, ensuring satisfaction before bulk delivery. Pipes are delivered securely, either loose or bundled, to guarantee impeccable packaging and transit safety. Our streamlined process ensures products reach you in optimal condition, ready for immediate deployment in projects. Contact us for tailored payment structures and sample availability in India.

Product details

|

Class of Pipe |

K-9 |

|

Coating |

Bitumen/Eposy/Polyurethane or as per customer requirement. |

|

Outside Onsite Protection |

Polyethylene Sleeving |

|

Size Range |

DN 80mm to DN 1200mm |

|

Standard Length |

5.5m/ 6.0m |

|

Usage/Application |

Utilities Water |

|

Material |

Ductile Iron |

|

Brand |

Jindal Saw |

|

Section Shape |

Round |

FAQs of Industrial Ductile Iron Pipes:

Q: How do Industrial Ductile Iron Pipes achieve such high impact resistance?

A: The pipes are manufactured from ductile iron, which provides excellent mechanical strength, and feature cement mortar lining along with external zinc and bitumen coatings. This combination ensures superior impact resistance, withstanding harsh handling and environmental conditions.Q: What types of fluids can these pipes safely transport?

A: Industrial Ductile Iron Pipes are suitable for the conveyance of potable water, raw water, wastewater, slurry, and a range of industrial fluids, making them versatile for various applications from municipal to industrial use.Q: When is customization of pipe thickness or coating recommended?

A: Customization is recommended for projects requiring specific diameters, lengths, coatings, or extra durability based on unique operating conditions. We offer customization upon request to meet precise engineering and design needs.Q: Where are these pipes predominantly installed?

A: These pipes are commonly installed in municipal water distribution, industrial fluid management, sewage systems, fire-fighting lines, and irrigation networks. Their robust performance makes them a preferred choice in infrastructure projects across India.Q: What is the process for ordering and receiving samples?

A: Upon client enquiry, we provide detailed product consultation. Samples can be handed over for inspection and testing, enabling customers to verify specifications before confirming a large-scale order, ensuring you receive the exact product for your requirements.Q: How does external protection prevent corrosion of the pipes?

A: A zinc coating topped with bituminous or epoxy overcoat acts as a barrier against environmental elements, significantly enhancing corrosion resistance and extending pipe life expectancy beyond 50 years under standard operating conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email